Al Newberry, PE Owner of FEMech at His Desk Download Practical Guidelines for Selecting Quality Fabricators of FRP Tanks and Pipe |

INTRODUCTION Fiberglass Reinforced Plastic (FRP) is used in a wide range of applications including automotive, tub and shower, marine, and corrosion resistant. When properly designed and fabricated, fiberglass is the material of choice, in terms of cost and reliability, for many corrosive applications.

RTP-1 DESIGNER QUALIFICATION This is to confirm that the Al Newberry, PE meets the new RTP-1 designer requirements. The RTP-1 Qualified Designer is the person(s) in direct charge of performing the engineering design of RTP-1 certified tank(s) and is experienced in the use of this Standard. The designer meets these requirements: (a) Completion of an engineering degree, accredited by an ABET accredited University, requiring the equivalent of at least 4 yr of study that provides exposure to fundamental subject matter relevant to the design of tanks and pressure vessels, plus a minimum of 5 yr of experience in the design of related tanks and pressure vessels including design calculations for pressure, sustained and occasional loads, and cyclic or thermal loading conditions. (b) Professional Engineering registration in one or more of the states of the United States or provinces of Canada or alternatively recognized by a jurisdiction outside the United States or Canada. At least 5 yr direct experience with design and fabrication including materials selection of FRP tanks and vessels using the RTP-1 Standard, ASME Boiler and Pressure Vessel Code, Section X, EN 13121 and other recognized international fiberglass vessel and tank codes and standards. FIBERGLASS ENGINEERING Fiberglass reinforced plastic is an advanced material, and the proper design of fiberglass tanks, pipe, duct, stacks and chimney liners requires specialized expertise. Fiberglass Engineering Mechanics specializes exclusively in fiberglass for corrosion resistant applications and has a worldwide practice. In addition, FEMech is actively involved in ASTM and ASME codes and standards for fiberglass tanks, pressure vessels, pipe and stack liners. FIBERGLASS INSPECTION

FIBERGLASS FAILURE ANALYSIS Failure analysis is one of the most challenging aspects of engineering and especially so for composite materials in corrosive service. Failure analysis requires a thorough understanding of correct and incorrect designs, fabrication methods and applications of the materials. FEMech has this expertise combined with extensive contacts with laboratories, material suppliers and other consultants throughout the FRP industry worldwide. SPECIALIZED EXPERTISE

|

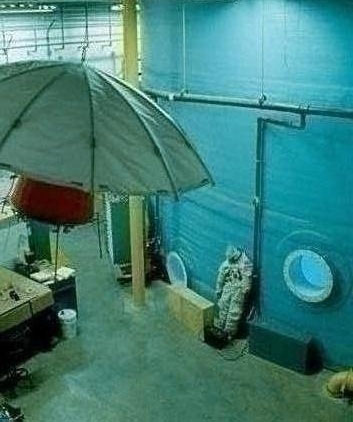

This 50 ft diameter x 25 ft open top, flat bottom tank was designed by Al Newberry, PE in 1992. The tank is located at the University of Maryland and is used for astronaught neutal buoyancy training. A space suit and a mock up of a satelite and be seen in the photo. The tank has performed flawlessly since 1993 when it was assembled. |

| Friday January 30, 2026 |

This 44 ft diameter x 60 ft tall HCl tank was designed by FEMech Engineering. FEMech also provided resident inspection services. There are two of these tanks which were shipped fully assembled to New Caledonia. Each tank weighs 120 metric tons. Photos of the tanks on board ship leaving the port can be seen in the "Photos" section of this website.

This 44 ft diameter x 60 ft tall HCl tank was designed by FEMech Engineering. FEMech also provided resident inspection services. There are two of these tanks which were shipped fully assembled to New Caledonia. Each tank weighs 120 metric tons. Photos of the tanks on board ship leaving the port can be seen in the "Photos" section of this website. Proper inspection of fiberglass requires specialized training, experience and equipment. Most generic inspection firms have neither the personnel, the expertise nor the equipment to provide industry standard inspection services for fiberglass. Fiberglass Engineering Mechanics has a team of experienced inspectors for both new and in-service equipment.

Proper inspection of fiberglass requires specialized training, experience and equipment. Most generic inspection firms have neither the personnel, the expertise nor the equipment to provide industry standard inspection services for fiberglass. Fiberglass Engineering Mechanics has a team of experienced inspectors for both new and in-service equipment.